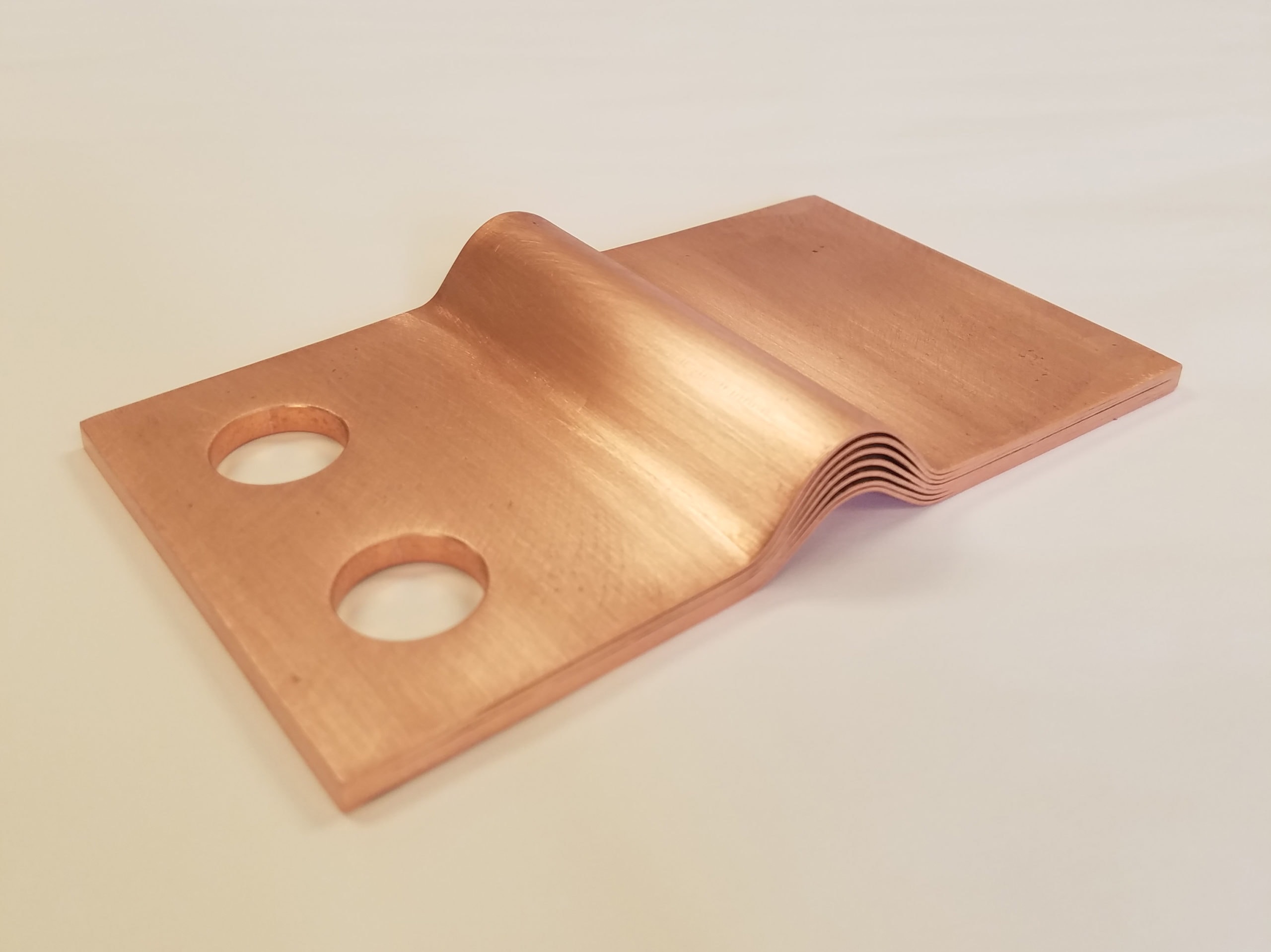

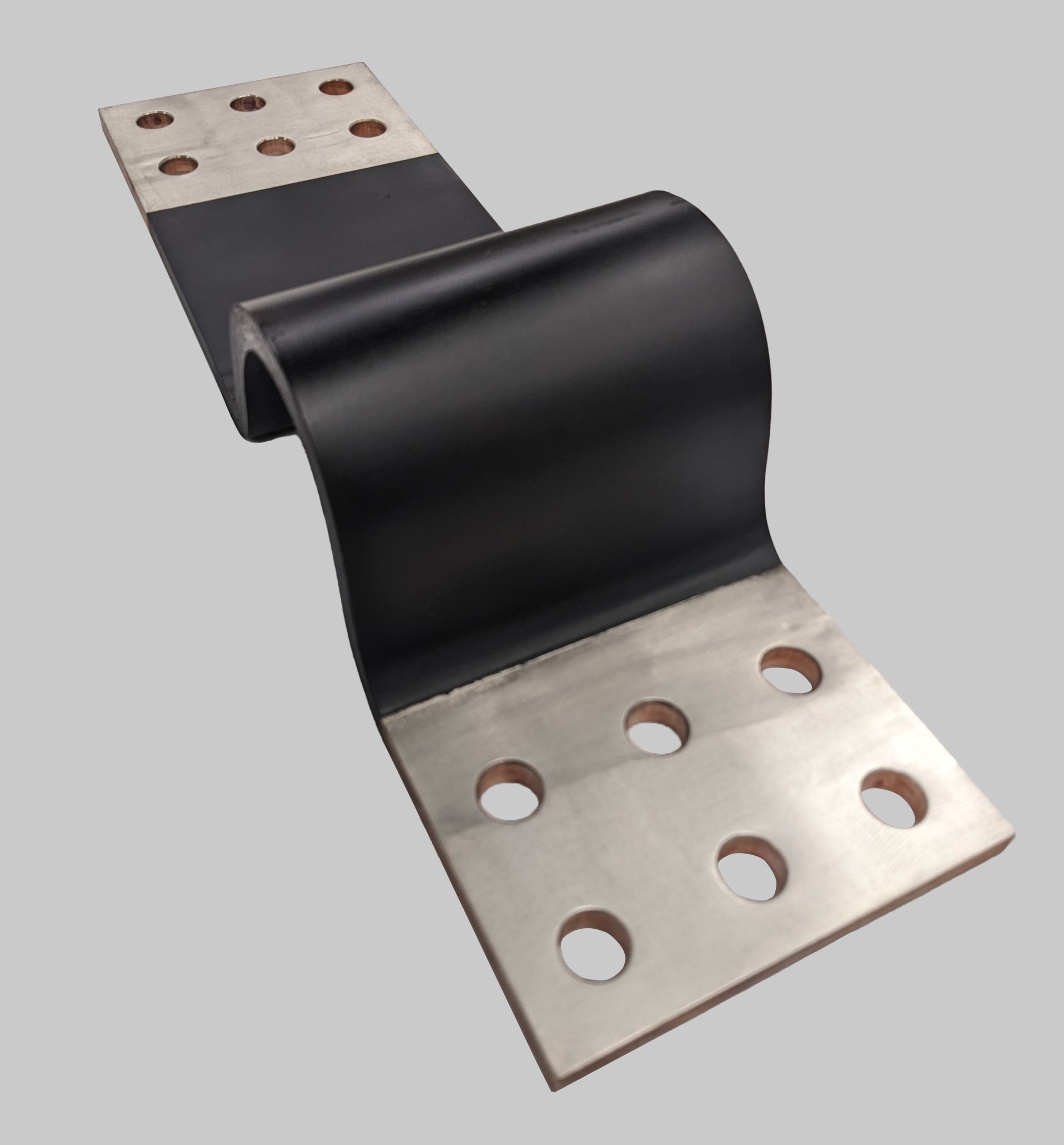

Custom Press Welded Copper Laminates/Flexible Bus Bars

What are Press Welded Copper Laminates?

Press welded copper laminates, also known as flexible bus bars, or laminates, are a series of copper strips press welded together.

Why do we use Press Welded Copper Laminates?

Press welded copper laminates alleviate vibration, component movement, or misalignment and are typically used as a substitute for solid bars and as flexible expansion joints to connect bus bars.

Press Welded Copper Laminates Capabilities

| Max Length | 4' feet |

| Max Width | 12" inches |

| Sheet Thickness Range | .004" - .090" |

| Typical Current Rating | 2,000 A |

| Max Current Rating | 5,000 A |

Lead Time

Our ISO-compliant facility can handle quantities for prototype to production with lead times as short as 2 to 4 weeks.

To learn more about these unique connector products, contact Erie Industrial today.

Typical Applications

- Power Distribution

- Mining

- Switchgear

- Nuclear Industries

- Chlorine Manufacturers

- Galvanizing lines